|

Cheapest pickings

Poor pricing is one of

the main reasons for irresponsible water use

Water subsidy to Indian industry is one of the classical cases of poor pricing of natural

resources leading to its massive exploitation. Using more water does not hurt Indian

industry, so it uses and abuses water recklessly.

The three components to

water cost in industries are:

Water

cess paid to pollution control boards based on the amount of wastewater discharged Water

cess paid to pollution control boards based on the amount of wastewater discharged

Cost of buying water from water suppliers, like the

municipality or private water suppliers Cost of buying water from water suppliers, like the

municipality or private water suppliers

Water self-sourced from river or groundwater comes

free of cost in most places, except where municipalities have put their foot down. Water self-sourced from river or groundwater comes

free of cost in most places, except where municipalities have put their foot down.

Water Cess: peanuts

Recently, the government of India revised the water charge for industry and

amended the Water (Prevention and Control of Pollution) Cess Act, 1977. The new water

rates were meant to be an impressive three times high than the current ones.

A closer look at the new

act, however, proved disappointing. The revised cost of water is still so cheap that it

will hardly be the incentive industry needs to improve its water efficiency.

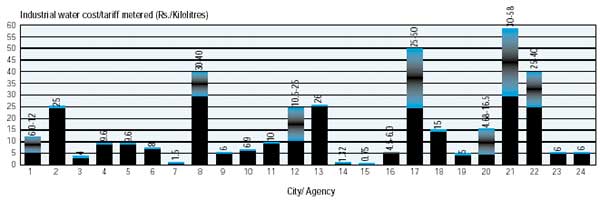

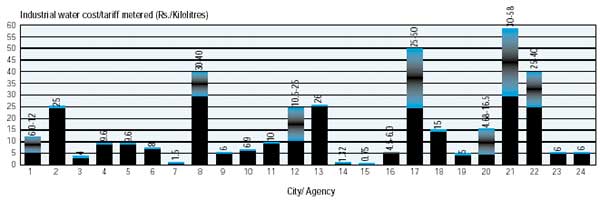

| Cost of buying water |

|

| 1. Hyderabad Muncipal water supply

& Sewerage 2. Guntur 3.

Ahmedabad Municipal Corporation 4. Baruch Municipal

Corporation 5. Rajkot Municipal Corporation 6. Surat 7. Veraval patan 8. Ankleshwar industrial area 9. Solan

10. Kerala Water Authority 11.

Nagpur Municipal corporation 12. Kolhapur Municipal

Corporation 13. Mumbai 14.

Orissa Water Supply & Sewage Board 15. Punjab Water

Supply & Sewage Board 16. Chandigarh 17. Madras Water Supply & Sewage Board 18.

Calcutta Municipal Development Authority 19. Rajasthan Water

Supply & Sewage Board 20. Jaipur 21.

Bangalore'97 22. Mysore'00 23.

Jabalpur 24. Lucknow |

Source: P S Rana, Integrated Urban Infrastructure investment

and HUDCOs leading programme, paper presented in the international IHSP seminar on

"Integrated Urban Infrastructure development held on February 1-4, 1995, New Delhi,

in Urban Statistics, Handbook 2000, NIUA, New Delhi, pp 103-104

* Change management finance, water tariff in major Indian cities, January 2002, pg no. 20

|

It is well-known that the consumption of water for

industrial cooling and boilers is thrice that of process water. Wastewater from cooling

and heating systems are less polluted and with little treatment can be easily recirculated

within the same system. With appropriate regulations or incentives, it is possible in most

cases to have closed-cycle systems for cooling and heating.

The new bill has fixed the

cost of water for industrial cooling and spraying in mine pits or boilers feeds at a mere

10 paise per kilolitre. This is 2-3 times lower than the cost of process water. At this

price, the cooling water cess of thermal power plants (TPPs) will constitute just 0.20 per

cent of total power generation cost (See table: Cost of power...). This is not enough to

induce generation from TPPs in India to reduce their cooling water consumption. In fact,

the new act has made sure that there is no water conservation for three-fourths of water

consumed (cooling water) by industry.

Very

expensive, elsewhere

Water pricing in

OECD countries and in USA are mostly based on average cost pricing or marginal cost

pricing. But along with water cost some of these countries have also introduced the

'polluter pay's principle' for the amount of water pollution load discharged by companies.

In comparison the Indian industry pays a pittance.

| Country |

Cost

(Rs/KL) |

| United Kingdom |

90.00 |

| Turkey |

80.50 |

Canada

|

76.00 |

| Hungry |

72.00 |

| Portugal |

55.00 |

| Spain |

51.00 |

| Netherlands |

51.00 |

France

|

42.50 |

| United States |

21.00 |

Source: OECD

(2001), using average US$ to Rs exchange rate of 2001 as 47.2.

|

The cost of process water,

Rs 0. 20-0.30 paise per kilolitre is not enough to encourage any sort of water

conservation by industries. In fact, if we consider that companies in water scarce areas

of Gujarat and Tamil Nadu are already paying Rs 25-60 per kilolitre it is obvious that

water cess rates are dirt cheap. From the point of view of the total production cost also,

the water cess is insignificant. For instance, in two major water consuming industries,

pulp and paper and iron and steel, at new rates the water cess will constitute about

0.1-0.2 per cent and 0.02 - 0.05 percent of the total turnover respectively.

The Water (Prevention and

control of pollution) Cess (Amendment) Act, 2003 is nothing but an instrument meant to

fatten the pockets of institutions such as the SPCBs and CPCB. The government has missed a

golden opportunity to introduce an effective and true economic instrument to reduce

industrial water consumption in India.

Cost of

buying water

When coming from public

supplies like municipal corporations or government agencies like industrial development

authorities in industrial complexes, water must be paid for. Industrial water tariffs from

public supplies in India is typically based on average cost pricing (rather than marginal

cost pricing) and ignore the opportunity cost of water (i.e., benefit foregone in

alternative use). Similarly, the effects of damages caused by industries in polluting

surfacewater and groundwater are ignored in determining water tariffs. Consequently, there

are no pollution taxes and/or effluent charges to be paid by industrial polluters. As a

result, from an economic viewpoint, excessive quantities of water are used, and excessive

pollution is caused.

Industry

can use water sensibly. When forced to.

Some of the best

water use practices, be it a thermal power plant, a fertiliser industry, or a refinery, is

evident in one of the most water stressed cities of the country, Chennai. The G.M.R Vasavi

power plant, Madras Fertilizers Limited and the Chennai Petroleum Corporation Limited are

a case in point. The least water consuming pulp and paper company, J K Papers, is located

in the water scarce Rayagada district of Orissa. The least water consuming sugar industry,

Natural Sugar and Allied Industry, is located in the water scarce district of Latur,

Maharastra. The first 'zero-discharge' textile mill in the country, Arvind Mills, is

located in Santej in Gujarat. This list goes on. These instances clearly prove that proper

pricing of natural resources is imperative for the proper management of natural resources.

Water use and water pollution in industries can be reduced only if water pricing is such

that it encourages industries to

conserve water.

| Cost of power generation from thermal power plants in India |

| Year |

Total power generation

from *TPP (million KWH) |

Cost of power

generation at TPP (Rs crores) |

Total wastewater

discharged (million m3) |

Total water cess (Rs

crores) |

Total water cess as %

of power generation cost |

| 2000-2001 |

37232 |

121860.99** |

27000.9 323 |

323.12*** |

0.265 |

* This also includes wind

power, which is negligible compared to TPP.

** Generation cost per KWH is Rs 3.27.

*** Assuming cooling water cess as Rs. 0.1 and process water cess as Rs. 0.30 per m3.

Source: Information related to power from annual report on the working of SEBs &

Electricity Departments, 2001-2002, Planning Commission and information related to

wastewater discharge and cess from "Water quality in India (Status and trends)

1990-2001, CPCB.

|

Varying

cost, varying efficiency

The cost of water supplied by public supplies varies widely not only between the states

but also within the state. In general, water availability of a given area determines the

cost of water there and this in turn has a direct bearing of efficient water management

(See:Water cost uneven all over India).

| Case

study on pulp and paper sector The Green Rating Project (GRP) of

New Delhi based Centre for Science and Environment (CSE), rates Indian industries on

environment performance. It has recently completed the rating of pulp and paper sector,

which is to be released shortly.

The analysis done by GRP on water consumption pattern in large-scale wood and non-wood

based pulp and paper companies indicates a clear coorelation between the water consumption

pattern and the regional location of the plants.

The findings are as

follows:

l Pulp and paper plants located in the water-stressed southern and western part of the

country consume less water than the plants located in the water-abundant northern and

north-eastern parts of the country.

l The average amount of water consumed by south Indian paper mills is about 160 m3 per

tonne paper produced. The same for companies located in western India is 165 m3 per tonne

paper.

l The average water

consumed by the north Indian paper companies is about 185 m3 per tonne paper produced. The

same for companies located in water abundant northeastern India is 205 m3 per tonne paper.

The analysis clearly indicates that in the northern and eastern part of the country, well

endowed with water, the water consumption in pulp and paper companies is high and in the

the west and south, which are water-short regions, the water consumption in paper

companies is low.

|

|