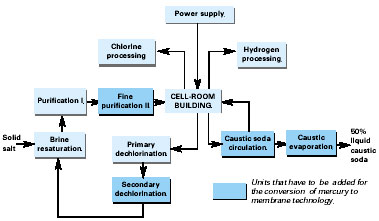

A reduction in mercury pollution can be achieved in three ways: switchover of mercury-using products and processes to non-mercury alternatives, control of mercury release through end-of-pipe techniques, and mercury waste management. The first is a preventive measure while the other two are control measures. Switchover to mercury alternatives may may substantially reduce the amount of mercury in households, the environment, the waste stream, incinerator emissions and landfills. In India, there are number of examples to prove that it is technologically feasible to change existing mercury cell plants to membrane cell plants. Companies like Punjab Alkalies & Chemicals Limited, Century Rayon Limited and NRC Limited, which were originally mercury cell plants, have now completely phased out their mercury cells and are using membrane cells. Although some changes are required, the existing infrastructure can be used for membrane technology as this would lower capital investment. As a number of companies have already switched over to membrane cell technology, it is clearly an economically feasible option. The major advantage is a substantial reduction in manufacturing cost, often to the tune of 20 per cent, because of the substantially lower energy costs. And above all, the cost incurred from severe environmental damages are reduced drastically. As many European companies are now finding out, the environmental liability of mercury cell plants can wipe out their businesses.

Controlling mercury emissions through end-of-pipe techniques, such as exhaust gas filtering, is appropriate for raw materials with trace mercury contamination, including fossil-fueled power plants, cement production, the extraction and processing of primary raw materials such as iron and steel, ferromanganese, zinc, gold and other non-ferrous metals and the processing of secondary raw materials such as iron and steel scrap. However, end-of-pipe control technologies, while mitigating the problem of atmospheric mercury pollution, still result in mercury wastes that are potential sources of future emissions. Mercury emissions from municipal and medical waste incinerators may be reduced by separating the small fraction of mercury-containing waste before it is burnt. In the US, for example, free household mercury waste collection has been successful in turning up significant quantities of mercury-containing products and even jars of elemental mercury. Also, separation programmes have proved successful in the hospital sector and a number of hospitals have pledged to avoid purchasing mercury-containing products. However, large-scale separation programmes are often difficult to implement. Mercury emissions from utility and non-utility boilers, especially for coal, may be effectively addressed through pre-combustion coal cleaning, reducing the quantities of coal consumed through increased energy efficiency, end-of-pipe measures such as stack gas cleaning and switching to non-coal fuel sources. Another potential approach might be the use of coal with a lower mercury content. Mercury emissions due to trace contamination of raw materials or feedstocks such as in the cement, mining and metallurgical industries may be reduced by end-of-pipe controls, and sometimes by selecting a raw material or feedstock with lower trace contamination, if possible. In cases of uncontrolled disposal of mercury containing products or wastes, possible reductions in releases from such practises might be achieved by making these practices illegal and by enhancing access to hazardous waste facilities. Policy imperatives Economic instruments, such as carrot-and-stick measures, are needed to make this switchover smooth and feasible. |